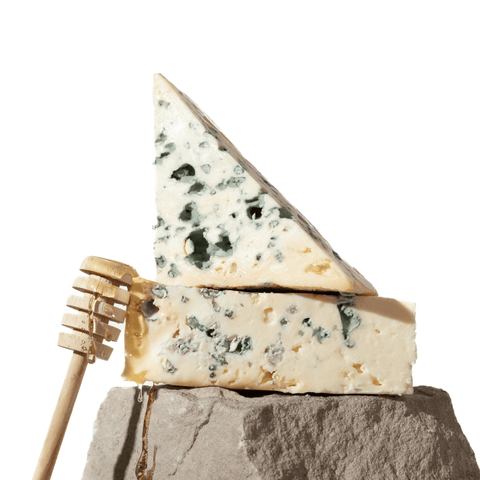

BLUE MURDER

A Blue to die for!

Mould ripened and meaty with fine threads of blue running through the creamy, white paste, so satisfyingly sweet and velvety that a mouthful can even take non-Blue cheese lovers to heaven!

Similar to our Strathdon Blue in the make, the square shaped moulds of our Blue Murder drain differently to the rounds and create a blue with a slightly smoother paste.

650g square

Try with a peated dram, they tend to be a touch sweeter and that always matches nicely with the salty note of a blue cheese, also a muscat or pudding wine. Easy to enjoy with savoury or sweet, easy to cook with.

- Blue

- Creamy

- Washed Rind

Typical values per 100g, Energy Kj1360 / 324kcal, Fat 26g, of which saturates 15g, Carbohydrate 2.9g, of which sugars Trace, Protein 20g, Salt 2g

Cow's Milk

The Making of our Blue Murder Cheese

Every cheese is crafted in Tain, ScotlandWe collect milk from local farms around Tain. Once the milk is received in our dairy, the milk goes through the pasteurisation process and will then be placed in vats. Cultures are added to begin the process of acidification. After a time, depending on how much acidity is required, rennet is stirred in, and the milk coagulates.

Cutting and Draining the CurdOnce a firm set has been achieved and depending upon how much moisture we wish to retain in any specific cheese style we will cut the curds. Bigger pieces of curd will retain more moisture and will be perfect for our BLUE MURDER. The curd is then stirred to help form a skin on each curd particle and to allow the process of syneresis to reduce the gel.

Shaping the cheese – MouldingOnce cut, stirred and drained the curd will be placed into moulds and will continue to acidify and drain but by removing most of the whey you steal the moisture, some warmth and a lot of lactose on which the cultures like to eat and develop, in this way you can stall the process so that you end up with the right moisture, size and texture depending upon cheese style.

Salting and MaturationSalt needs to be added both to flavour and preserve the curd. With Blue cheese we add salt by rubbing it onto the surface of the cheese. After around 5 days the cheese is pierced to allow the penicillium Roqueforte to spore and grow inside the cheese, this can take 14 days, then it’s wrapped in aluminium foil and held at around 3 centigrade for 2 months.